Ancora

Progettazione e produzione di linee complete per la finitura del prodotto ceramico

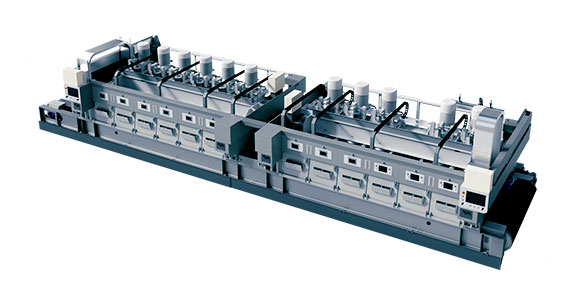

Ancora, storica realtà italiana specializzata nella produzione di macchinari per la finitura ceramica, che grazie alla costante R&D, presenta una nuova gamma di tecnologie per levigatura, lappatura, taglio, rettifica e trattamenti protettivi del materiale ceramico.

Italian passion

for ceramic technology

after sales

Shield Program

Attraverso il servizio di Customer Service l’azienda mette a disposizione dei clienti un pool di tecnici altamente specializzato, per programmare l’assistenza e prevenire eventuali fermi di produzione attraverso la verifica e il collaudo dei macchinari, appurandone l’operatività, l’efficienza e la funzionalità.

Sono preparati inoltre nel suggerire tutte le eventuali ottimizzazioni e nel fare confronti tra metodologie produttive in relazione ai materiali lavorati.

News